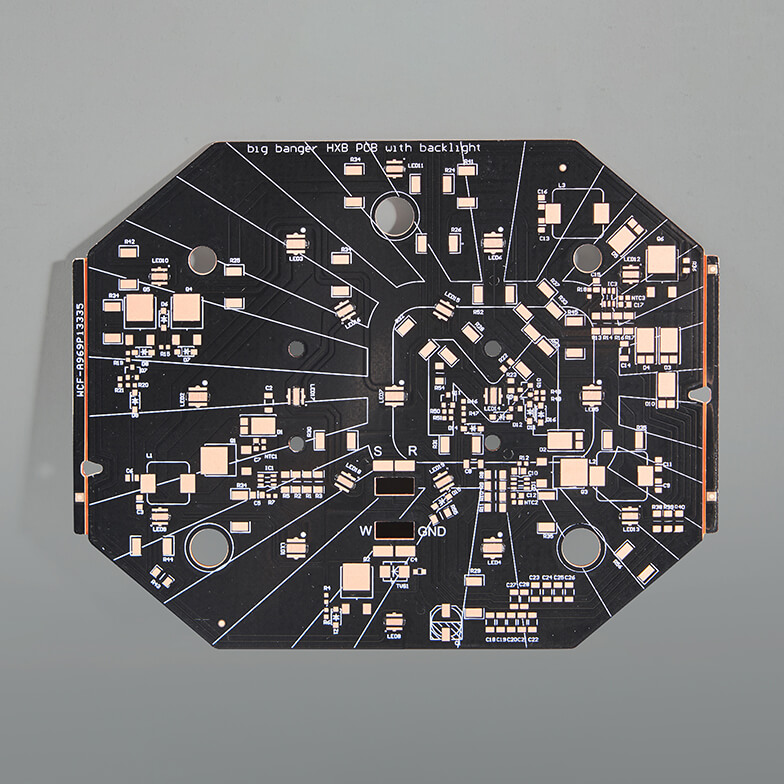

Copper Clad PCB

LEADHUI Copper PCB Overview

LEADHUI Copper PCB is a type of metal core printed circuit board (MCPCB) that features excellent thermal conductivity and mechanical stability. Unlike traditional FR4 or aluminum PCBs, copper-based boards provide superior heat dissipation and load-bearing capacity, making them ideal for high-performance applications.

Structure

The typical structure of a LEADHUI copper PCB includes:

- Circuit Layer (Copper Foil)

Conducts electricity and forms the electrical pathway. - Insulation Layer

A thermally conductive but electrically insulating layer that transfers heat from the circuit layer to the metal base. - Metal Base Layer (Copper Core)

Offers excellent thermal performance and mechanical strength, better than aluminum or steel substrates.

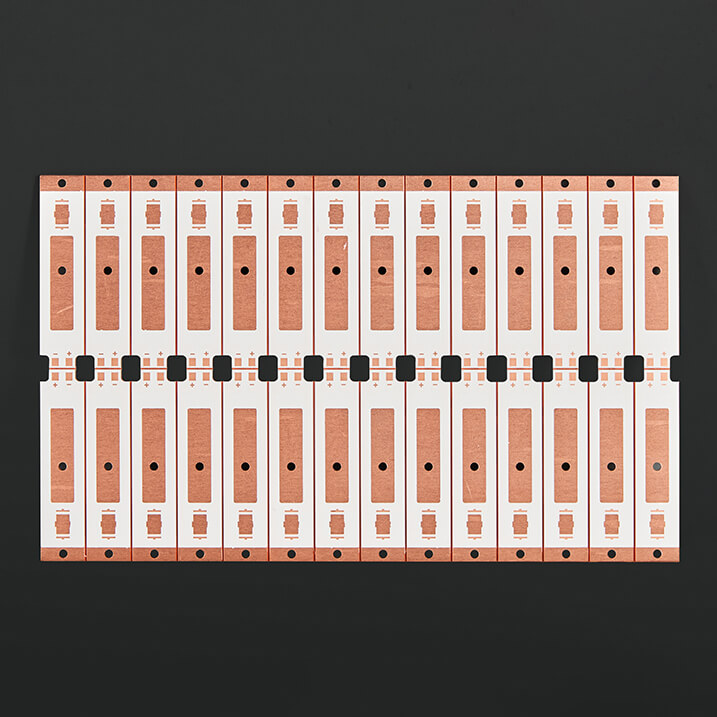

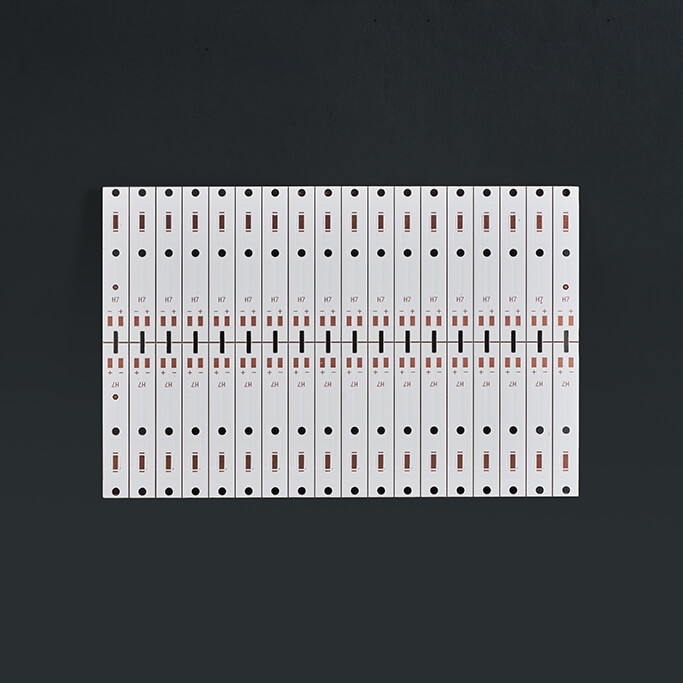

For more advanced applications, multi-layer copper PCBs can also be manufactured by laminating multiple circuit layers with insulating materials over a copper core.

Performance Features

- Superior Heat Dissipation

Copper has thermal conductivity of up to 398 W/m·K, far exceeding aluminum (~200 W/m·K) and FR4 (~0.3 W/m·K). - High Mechanical Strength

Ideal for applications with strong vibrations or mechanical stress. - Stable Dimensional Tolerance

Copper’s rigidity minimizes thermal expansion and improves long-term reliability. - Strong Current-Carrying Capacity

Supports high-current designs without overheating, suitable for power electronics.

Application Areas

LEADHUI Copper PCBs are widely used in industries where high heat and current loads are present, such as:

- High-power LED modules

- Power supply systems

- Electric vehicle (EV) chargers

- RF and microwave communications

- Solar panel controllers

- Motor control systems

- Automotive electronics

- Industrial automation

Advantages After PCB Fabrication

- Extended lifespan of components

Reduced heat stress on components leads to longer product life. - Improved circuit reliability

Stable performance even under high thermal cycles. - Compact design possibilities

High heat tolerance allows for smaller PCB sizes and tighter component layout. - Better EMI/EMC shielding

Copper’s high conductivity helps minimize electromagnetic interference.